| Parameter | Description |

|---|---|

| Grade | G40 |

| Shots | 230 |

| Max Length | upto 9 mts |

SURFACE TREATMENT

Powder Coating:

At Vijay Engifab India Pvt Ltd, we have a dedicated paint department that provides a powder coat system to finish our Customers raw product. We have a streamlined process of painting, packaging, and delivering to get each product to you efficiently and in quality shapes. We have a team of in-house painting experts to provide top-quality results to our customers. Also, our company works to keep our employees continuously up to date with new products and processes. We have regular meetings to ensure a quality environment and work method. We retain relationships with suppliers to ensure awareness of the latest and best products and methods. In addition, we provide in-house training for our employees to ensure the best work and to cut down on problems.

Our plant is fully automatic and conveyorised INTECH make with following details:

Plant Area : 15000 Sq. Ft. PT : Spray pre-treatment process. Drying oven: After Spray pre-treatment article will travel inside oven for total drying. Booth : Manual Coating booth (SS) with size: 6.5Mx3Mx3.4M- 2Nos. Oven : Camel back Powder Curing Oven with heat exchanger & LPG fired: size: 3500x600x1500mm Powder coating equipment's: Gama 4 Nos. DM water plant : installed own DM water Plant capacity 3000 lit/hr. ETP Plant: ETP plant as per required capacity and approved with MPCB Laboratory: We have well equipped laboratory as per IS/BS standard.

Specifications

CONVEYOR LENGTH 135 MTR.-

Loading (article size 3500MMX1500MMX600MM), (LOAD BAR SIZE 2500mm)

9 Tank pre-treatment.

Online water drying oven.

2 Reciprocators for automatic powder coating.

4 Manual powder coating gun.

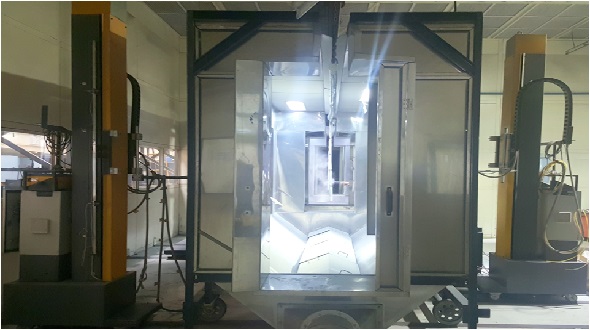

2 Nos. S.S.Roll in roll out powder coating booth.

Automatic oven temperature & conveyor interlocking system.

Max load 150Kg,16 MM baking facility.

Blasting & Painting: